Creating value through material recovery and process innovation

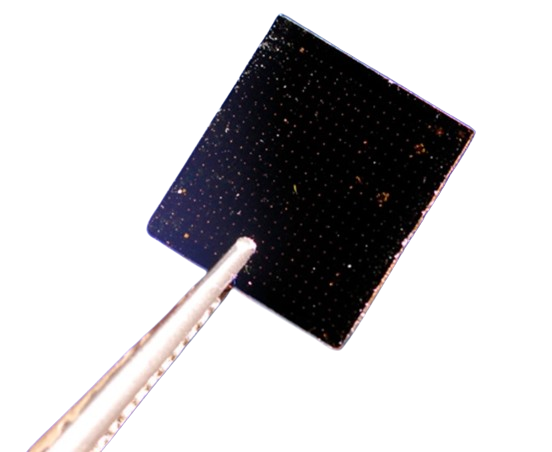

Mechanical Processs

In this process lithium-ion batteries of various formats, chemistries, and charge states through a mechanical method. This method disassembles the batteries into inert substances, reducing the risk of fire or explosion, and then divides the materials into two primary categories: battery materials, known as black mass, and a combination of copper, aluminum, iron and plastic.

Hydrometallurgy Process

In this process, the battery materials, known as black mass, are anticipated to undergo processing in the hydrometallurgical circuit to yield essential battery materials, such as battery-grade lithium carbonate, Cobalt oxalate, Cobalt hydroxide, Nickel sulphate, Nickel chloride,

Manganese sulphate and Graphite. By reintegrating these products back into the lithium-ion battery supply chain, Animesh recycling successfully bridges the gap between the end-of-life and manufacturing stages, ensuring environmental and economic sustainability.

Metal Extraction Process

In this process, the battery materials, known as black mass, are anticipated to undergo metal extraction process yield essential materials, such as single layer graphene. By reintegrating these products back into the lithium-ion battery supply chain, Animesh recycling successfully bridges the gap between the end-of-life and manufacturing stages, ensuring environmental and economic sustainability.